how does a 3/8 compression fitting work

Accordingly do you use Teflon tape on compression fittings. Packy MA you will have to put a short piece of 38 tubing into the branch of the tee.

Brass Compression Female Connector 3 8 Compression X 1 4 Fpt Brass Compression Female

It is important to choose the appropriate fitting for the application.

. Male end into your hose and compression end over the new tubing. These parts are attached to each other by first sliding the nut onto the tube or pipe and then connecting the compression ring. Whats the Thread on a 38 Compression Fitting.

PLACE THE FITTING ON. Slide the nut to the fitting and hand tighten clockwise. Misalignment will cause a leak.

20580 Use with mild motors up to Predator Compression Release 212. Be careful not to cross-thread the nut. These will not work as stock replacements 14 thg 2 2022 The 3rd generation Predator 212cc is a non-hemi engine with 25mm.

Using a spanner and a pair of grips the nut is tightened. Your local plumbing store will have adapters most hose bibs are 34 you wont need that at all feeding a 38 from under the sink by adding a shutoff valve with 2 ports or another method of adding a T would make sense to me. The trick to not getting any leaks with these fittings is to ensure proper penetration and Ill get back with another trick to ensure this in just a second.

Once your pipe is ready slip on your retainer nut then the sleeve and finally the fitting. Im making some fittings for my lamps and I want them to attach to the tube which will make the stem of my lamp using a compression fitting. 38 compression to 38 FIP.

Then buy a 38 male x 38 compression adapter. Slide the nut over the ring and thread it onto the fitting until it is hand-tight. 38 tubing in most common usage is ACT type tube and the OD is EXACTLY 38.

Mar 3 2020 at 2248. Click to see full answer. In the case of softer materials the fitting may include an insert to support the inside diameter of the tube thereby assuring a good seal to its outside diameter.

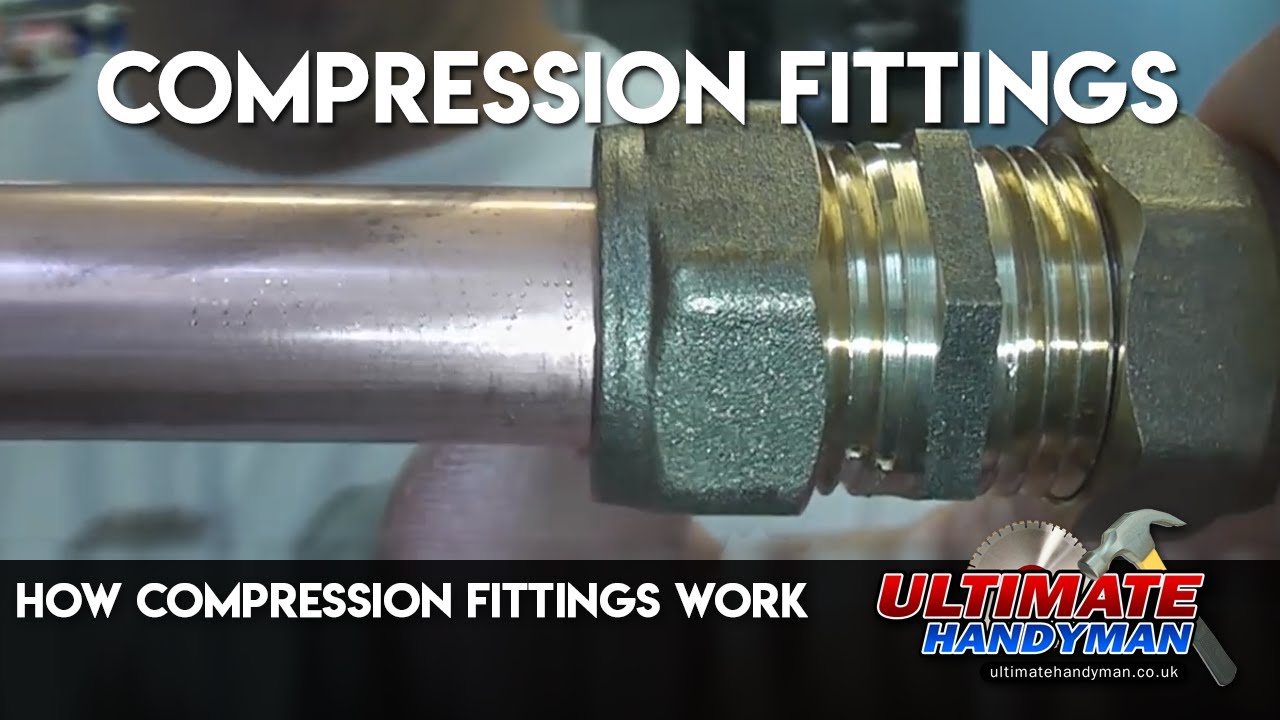

This exerts pressure on the olive and bites it onto the pipe. Compression fittings for attaching tubing commonly have ferrules in them. I dont have a spec on the ferrule but obviously it is just right to fit smoothly over the tube.

Compression fittings are based on tube size. 3 hours agoTapped for pulse fitting to run fuel pumps or venting. Compression outlets typically consist of the pipe a nut a compression ring and the fitting itself.

It is usually shaped as a near conical allowing for a better seal with less force applied. The ring the nut and the seat. Hold the fitting against the pipe and slide the compression ring up against the fitting.

Some people also believe that you need to use a sealing compound. Compression fittings are very versatile but many people are not confident when using them. The tube that Im using on this one is 38th OD.

As the nut is tightened the compression ring is pressed into the seat causing it to compress against the pipe and the compression nut providing a watertight connection. The nut and ring are placed on the pipe then the fitting is placed at the pipes end. Compression fittings use a small nut.

As the nut is tightened against the fitting the brass ring is deformed against the pipe itself creating a strong seal. So with your retainer nut and sleeve in place nows a good. Compression fittings for PEX operate in much the same way as compression fittings for copper or other plastic piping.

As the nut tightens up against the fitting it squeezes the seal into a chamfered area on the fitting the angle of which. Compression fittings work by the compression of an olive between two tapered surfaces and the pipe. Pin On Copper Plumbing Pin On Products Ltwfitting 3 8 In O D Comp X 1 4 In Mip Brass Compression Adapter Fitting 5 Pack Hf686405 The Home Depot Brass Brass.

A compression fitting is a type of coupling used to connect two pipes or a pipe to a. A compression fitting is a fitting used in plumbing and electrical conduit systems to join two tubes or thin-walled pipes together. Compression fittings work by the compression of an olive between two tapered surfaces and the pipe itself.

Tighten compression fittings firmly with two wrenches to crimp the ferrule onto the pipe Photo 3. In general these fittings are made up of three components. These components are compressed so that they can keep the connection watertight or in other words leak-free.

Fit one wrench onto the body of the fitting and hold it so that the fitting doesnt move. Buy a self-lighting torch. Compression fittings can be applied to materials ranging from plastic and rubber to the hardest metals.

The hard tubing compression fitting usually also has two more o-rings. Predator 212 Hemi to stainless valves. Position the Parts and Join Them.

Similarly one may ask how does a compression fitting work. A compression fitting is a type of coupling used to connect two pipes or a pipe to a fixture or valve. Also make sure the pipe or tube goes straight into the fitting.

38 tubing in most common usage is ACT type tube and the OD is EXACTLY 38. While these fittings may require more work than quick-. The goal here is to use as many off the shelf parts as I can so Im trying to work with standards.

1 is front pass cylinder on the compression stroke. EdBeal you should probably turn that into an Answer. Furthermore can you over tighten a.

In instances where two pipes made of dissimilar materials are to be joined the fittings will be made of one or more compatible materials appropriate for the connection. Fittings for hard tubing are marked with only one number which stands for the OD Outer Diameter of the tube it can accommodate. If the fitting leaks after you turn on the water try tightening the nut an additional one-quarter turn.

I dont have a spec on the ferrule but obviously it is just right to fit smoothly over the tube. Using a spanner and a pair of grips the nut is tightened. Compression fittings use a small nut to compress tubing to create a secure seal to a fixture or valve.

The two surfaces are the body of the fitting be it a valve connector or any other type and the nut. As the name implies the watertight seal of the fitting is reliant on the compression of a rubber washer. A hard tubing compression fitting consists of more parts but the two most important are the base and the locking ring.

Compression fittings are based on tube size.

B K 3 8 In X 3 8 In X 1 4 In Compression Tee Fitting Lowes Com Compression Fittings Brass Fittings

Lead Free Brass Male Connector 5 8 Compression X 3 4 Mpt Brass Lead Free Brass Color

How Compression Fittings Work Youtube

B K 1 4 In X 1 8 In Compression X Mip Adapter Coupling Fitting Lowes Com Brass Fittings Fittings Compression

Everbilt 3 8 In Chrome Plated Brass Compression Nuts And Brass Sleeve Fittings 2 Pack 800999 Plating Chrome Chrome Plating

Brass Compression Female Connector 1 4 Compression X 3 8 Fpt In 2022 Brass Compression Stud Earrings

B K 5 8 In X 1 2 In Compression X Fip Adapter Coupling Fitting Lowes Com Fittings Compression Couple Fits

Pin On Steel Mart Usa Products

Octopus Orb Brass 90 Elbow Orb 5 To 3 8 Compression Oc17236 Hose Box Orb Brass

Dial 1 4 In H X 3 8 In W Brass Compression Union Copper Tubing Brass Dial

Eastman Brass 5 8 In Compression X 1 4 In Compression Quarter Turn Stop And Waste Valve Lowes Com In 2021 Compression Turn Ons Valve

Theworks 3 8 In O D Inlet X 3 8 In O D Outlet X 1 4 In O D Compression Outlet Stop Valve Tee Adapter Mts134 The Home Depot Adapter Hydronic Heating Systems Valve

Compression Fitting Union 1 4 In 785 304d Advance Auto Parts In 2022 Radiator Fan Automotive Repair Fittings

How To Use A Compression Fitting Compression Plumbing Tutorial Plumbing For Beginners Youtube

Brasscraft 3 8 In X 3 8 In Dia Threaded Coupling Fitting In Gold 114 Fsv 6 P Fittings Couple Fits Brass Fittings